| PVC foam core pipe machine, PVC foam core pipe extrusion line |

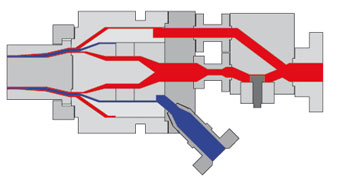

The heart of the foam core pipe line is the Feedblock. The feedblock designed by our company enables the production of pipes up to max. 630 mm diameter.

The use of foam core pipes for low-pressure applications, such as sewage, drain pipes and cable ducts has seen tremendous growth over the past years. Currently pipe diameters of 32 mm to 630 mm are on the market.

Major advantages offered by foam core pipes:

- weight and cost savings

- higher productivity because the same output yields higher pipe footage

- usage of regrind possible

- existing lines can easily be adapted at low investment

- production process is very similar to that of solid pipes

- same couplings used as for solid pipes so no changes needed at processors plants

- We offers turnkey project for PVC foam core pipe production

|

|

|

|

The 25% cost saving solution!

We offer PVC foam core pipemachine for production of 3-layer PVC-pipes. Cost savings in production of up to 26% mainly on material savings by an foam core is the vital argument to compete with compact pipes in non-pressure applications!

Using virgin or recycling material has been the major advantage of this technology. Standard fitting systems, as known for compact pipes, can be used. The high outpu using a combination of two or three extruders in a production setting. Smaller dimensions are using double-strand technology. Another big advantage of our technology is the low-cost formulation recommended.

Pipes are usually produced to national standards. The main standards are EN 1401-1 and EN 13476 as well as US F 891. Wall thickness is determined in a way that ring stiffness classes of 2, 4, 6 and 8 kN can be achieved. Highest classes already done are 16 kN.

A typical application is sewerage pipes reaching a market share of 85 % on comparable applications in Europe, which have totally erased compact pipes for this application. There is a clear potential for massive growth in the region of middle and near east.

Development priorities are higher filling of foam core and skin, 3-extruder settings with colouring of the outside skin only and extended use of recycling material in the middle layer.

|